Clad Aluminum Alloy Sheet

As an alternative one side can be clad with a non braze alloy e g.

Clad aluminum alloy sheet. 0 05 0 1mm ultra thin h65 h90 t2 aluminium clad sheet 5 series 6 series for cable lightweight copper clad aluminum sheet with high electrical conductivity high strength copper clad aluminum plate with good heat dissipation. The trade name of this aluminum laminate as originated by the aluminum company of america is alcad. Corrosion resistance and machinability are rated as fair though the addition of chromium provides good stress corrosion cracking resistance in 7075 aluminum sheet products. The trade name of this aluminum laminate as originated by the aluminum company of america is alcad.

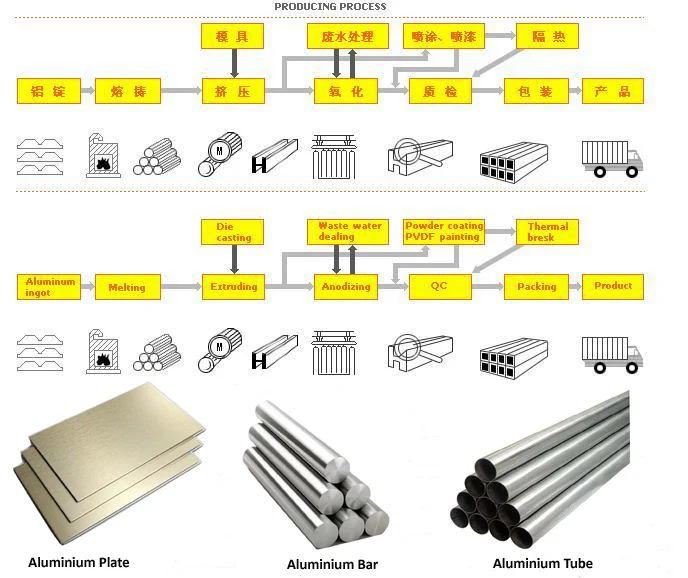

Maximum fl exibility is produced by our versatile rolling equipment which is able to supply aluminium sheet to many different tempers. Cladding in general is the application of one type of substance or material over a different material effectively creating a protective layer on the underlying material. Alclad aluminum sheet is a late game component used for building mk 5 conveyor belts and lifts among other things. Alloy 7075 aluminum coil and sheet have been and remain the baseline standard with a good balance of properties required for aerospace applications.

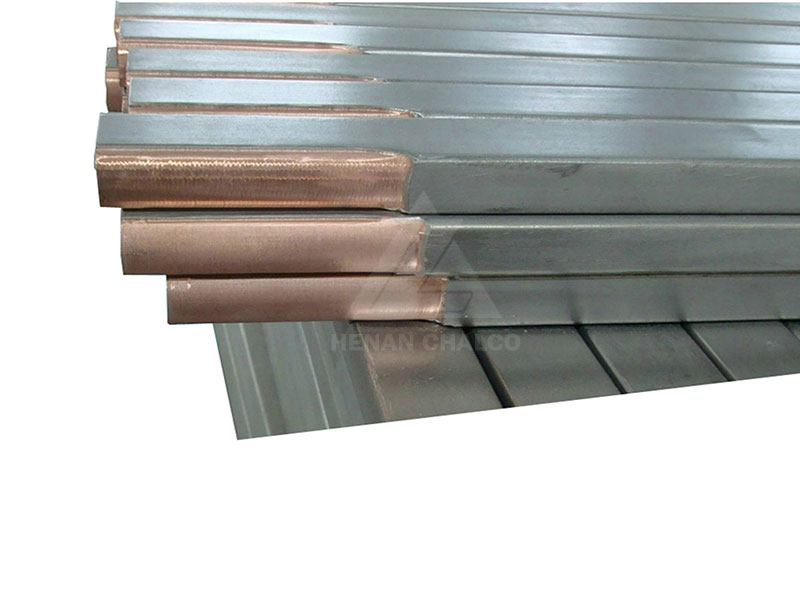

7075 is the strongest aluminum with the strength of many steels while retaining aluminum s lightweight qualities. An extremely thin sheet of pure aluminum laminated onto each side of an aluminum alloy sheet improves the corrosion resistance with little impairment of strength. Alclad is a corrosion resistant aluminium sheet formed from high purity aluminium surface layers metallurgically bonded rolled onto to high strength aluminium alloy core material. It has a melting point of about 500 degrees celsius or 932 degrees fahrenheit.

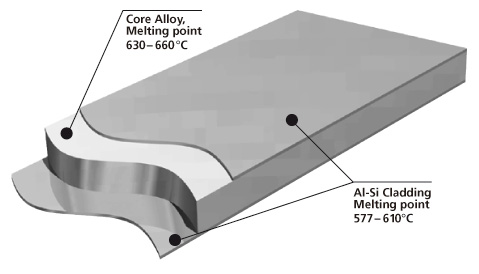

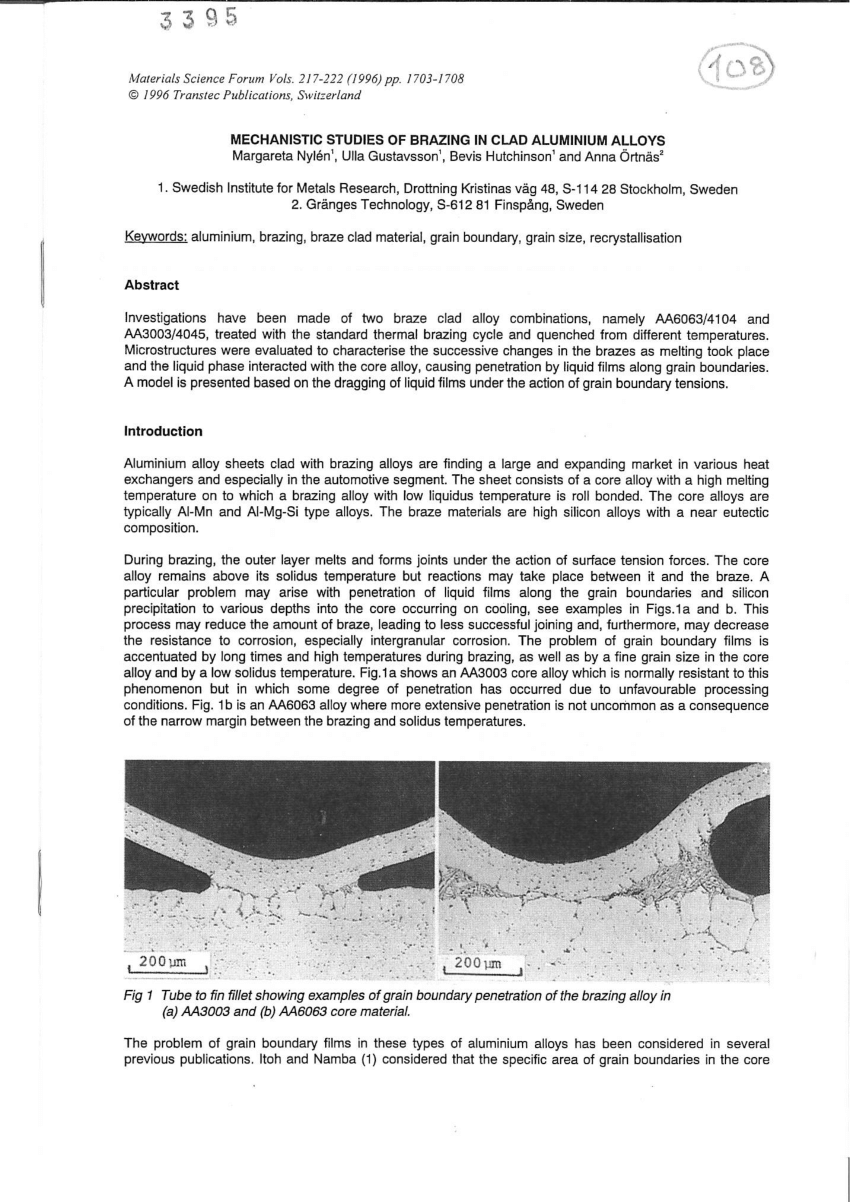

Aluminium brazing sheet is manufactured by roll bonding techniques to clad a core alloy ingot on one side or both sides with a low melting alsi alloy. Aluminum sheet plate 7075 t6 clad 9 products aluminum sheet plate 7075 clad is normally used for aerospace military and automotive applications. From this trade name the adjective clad and the verb cladding have been derived. Depending on the desired final properties the core is either homogenized or not before the cladding operation.

7075 aluminum is among the highest strength alloys available and used in highly stressed parts. Clad aluminium enfield tubes offers a range of brazed aluminium sheet and coil for vacuum brazing applications and controlled atmosphere brazing applications cab. From this trade name the adjective clad and the verb cladding have been derived. Aluminum cladding is cladding that is created using a thin coating of aluminum on the exterior of the product.