Cnc Drilling Galvinized Sheet Metal

Cnc plasma metal cutting machine for carbon stainless steel pipe with cheap price it is widely applied in industries such as machinery automobile shipbuilding petro chemical war industry metallurgy aerospace boiler and pressure vessel locomotive etc it is suitable for all kinds of metal materials such as steel copper aluminum and stainless steel can be processed.

Cnc drilling galvinized sheet metal. Focused on procedures used in the structural steel petroleum pipelines sheet metal and chemical refinery welding industries. The material can also be hazardous to your health when you are cutting it whether you are using a welding machine drill engraver or other cutting tools. Just make sure to use the oil use a good powerful drill and steady pressure. Drilling a hole in sheet metal with a twist drill is a rather straightforward operation.

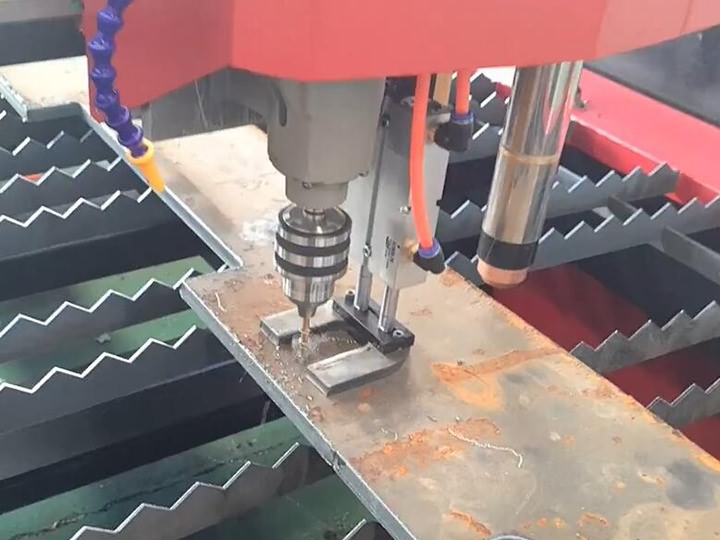

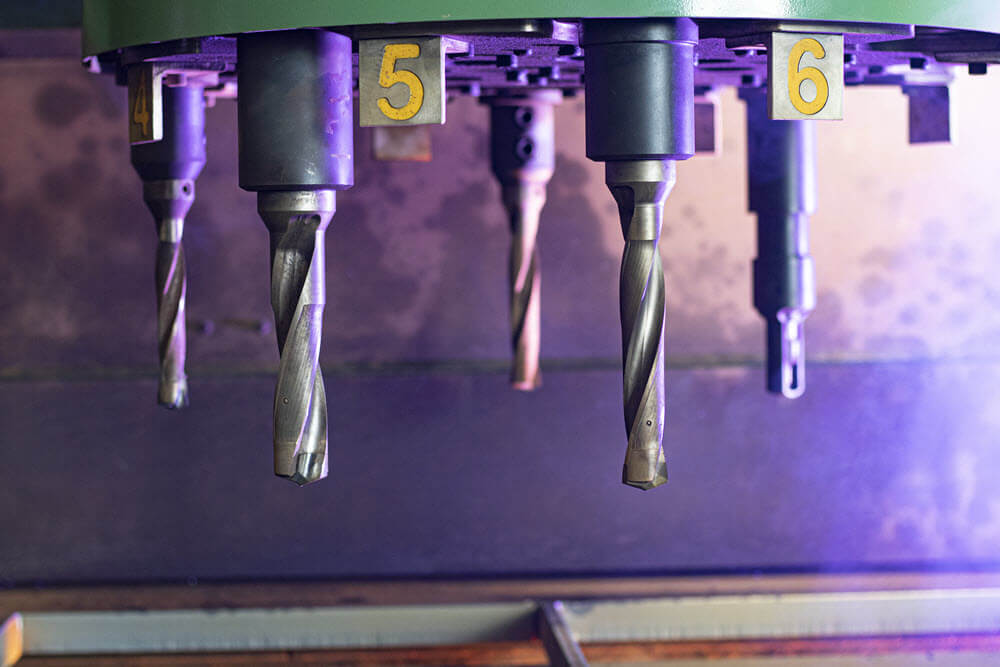

Capable of drilling counterbore chamfering tapping and light milling jobs. Eagletec cnc drilling machine et drill 1000x2000mm is a metal processing solution. The sheet metal gauges are neither standard nor metric the numbers are independent of measurement systems and do not mean actually measured value. Step drill bits are designed to drill holes in sheet metal and other thin materials.

It s essentially the same as drilling normal metal. Galvanized steel which is treated with zinc to prevent rust is useful for tools equipment structures buildings and outdoor items. It is widely used in metal plate rectangular tube flange square linear guideway and other industries. Six sigma green belt using the lean six sigma methodology aimed at improving processes with the purpose of increasing their profitability and productivity.

They re just the thing when you need a perfectly sized clean hole in a steel junction box electrical service panel or even a stainless steel sink. After you drill the hole it is possible to provide adequate corrosion protection for the drilled hole. Drilling into galvanized metal is no different than drilling a hole in standard carbon metal with the exception that the protective zinc coating does not protect the drilled hole. You start off by drilling a small diameter pilot hole and then drill gradually larger holes until you get.

You don t want high rpms but a steady constant speed. You can use the chart to confirm the metal thickness for the cnc machining process or material selection. Effective processing size 1000x2000mm is the most common standard size. A step drill bit for metal allows you to drill holes in a variety of diameters and some will drill through.