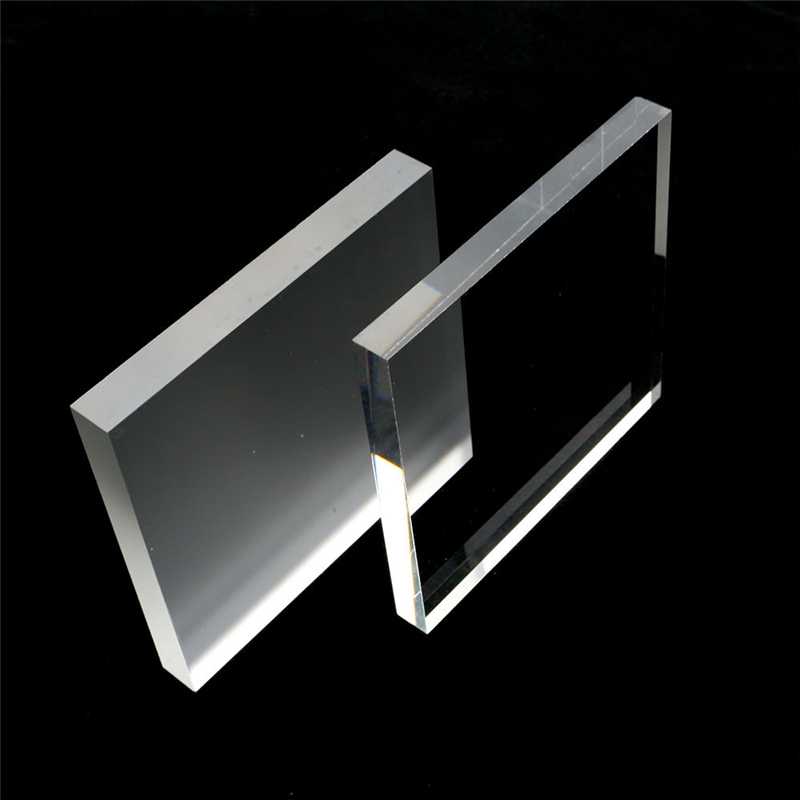

Cold Bending Acrylic Sheet

To bend sheet plastic and acrylic you will need.

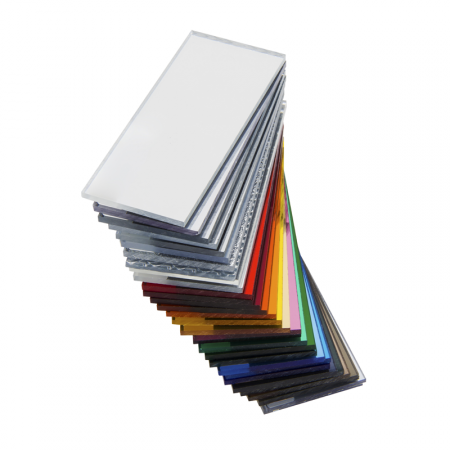

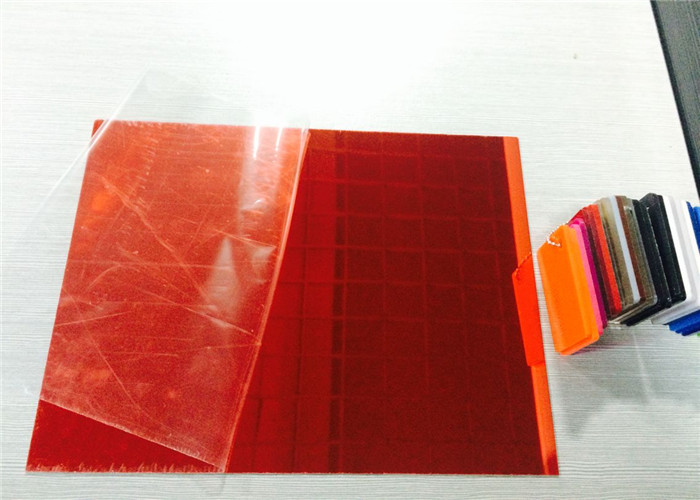

Cold bending acrylic sheet. Spectar supposedly looks and handles much like acrylic but with the surprising property that it can be cold formed without breaking or whitening and exhibits a memory effect holding a cold bend until reheated. Forming but is viable for bending sheet thicknesses of up to about two inches. Heat source small projects with bends that are close together will need upon heat source which can be easily aimed at small areas. Wear gloves as you do this to avoid burning your hands.

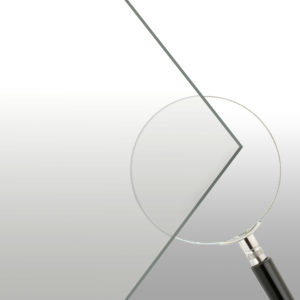

Plexiglas sheet cold forming. This radius is applied in all cold bending procedures. Plexiglas acrylic sheet heated from one side may vary from one. The recommended radius of curvature should be a value greater than 180 times the thickness of the sheet for plexiglas g sheet and 300 times the thickness for plexiglas mc sheet see table below recommended minimum radii of curvature for cold formed plexiglas.

The two best tools for this are a small butane torch the type used in the kitchen work well or you can also use an embossing heat tool used by card makers and scrapbookers to melt and apply embossing powders. Set the sheet of acrylic across the rests on the strip heater and turn it on. Minimum cold forming radius sheet thickness x 100. In the image above the values are all in inches but the principle often holds even if the units are in mm.

Cold forming plexiglas sheet can be cold formed bent at room temperature in a smooth arc and held to a radius by forcing the material into a curved channel support. It is given by multiplying the thickness of the sheet by 100 i e. Be sure that the marked line is above the heating element. A typical forced circulation air oven is shown.