Convert Sweep To Sheet Metal Solidworks

I m trying to convert this imported part to sheet metal.

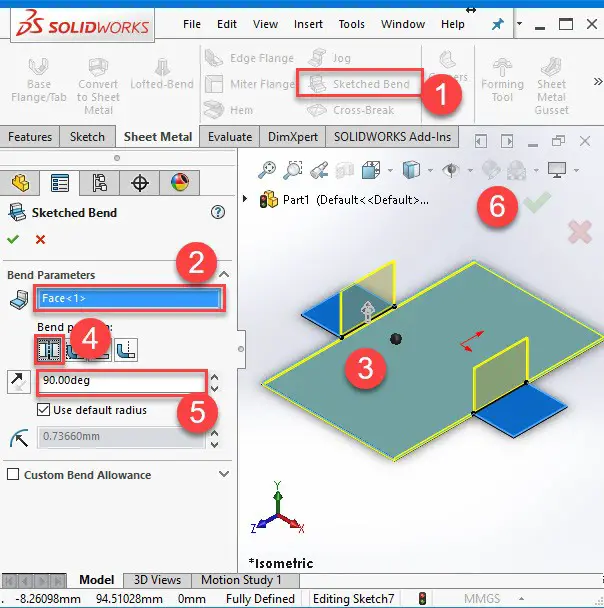

Convert sweep to sheet metal solidworks. I then click on connect all bends then hit the check mark for ok. Haven t really worked with sheet metal so i m not really sure what i m doing wrong. Create the solid part. Enter the material thickness you want.

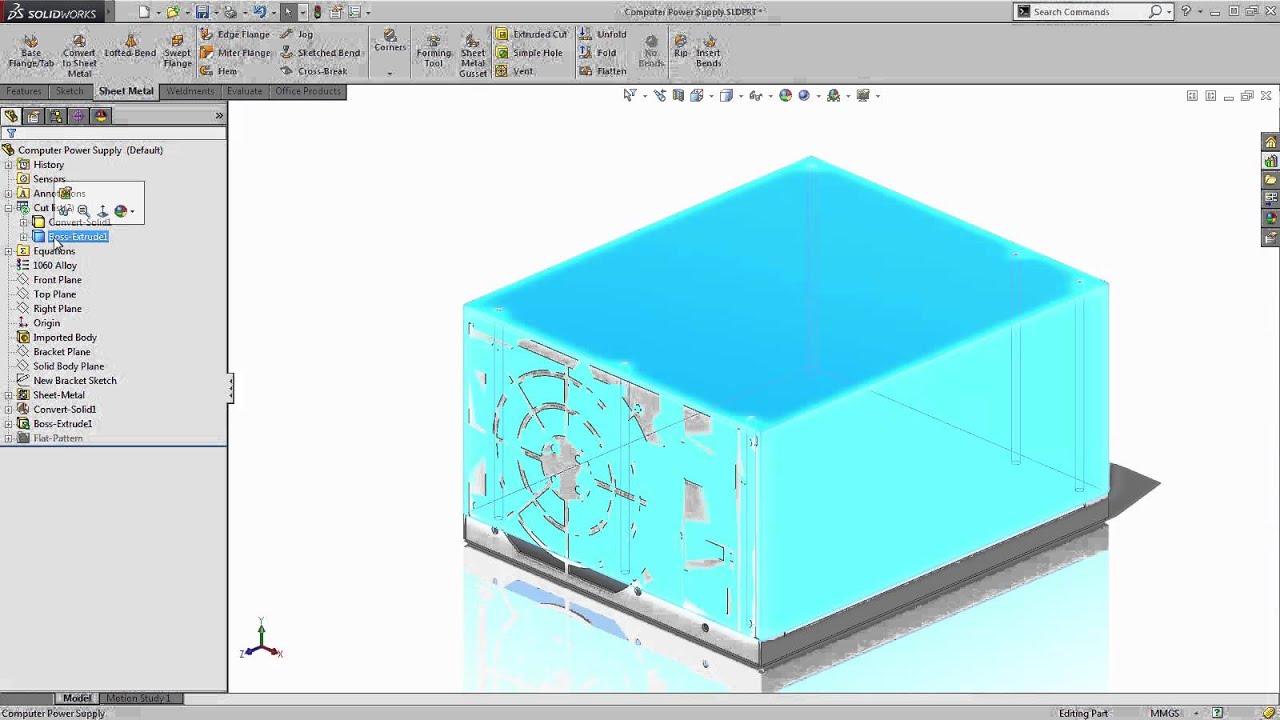

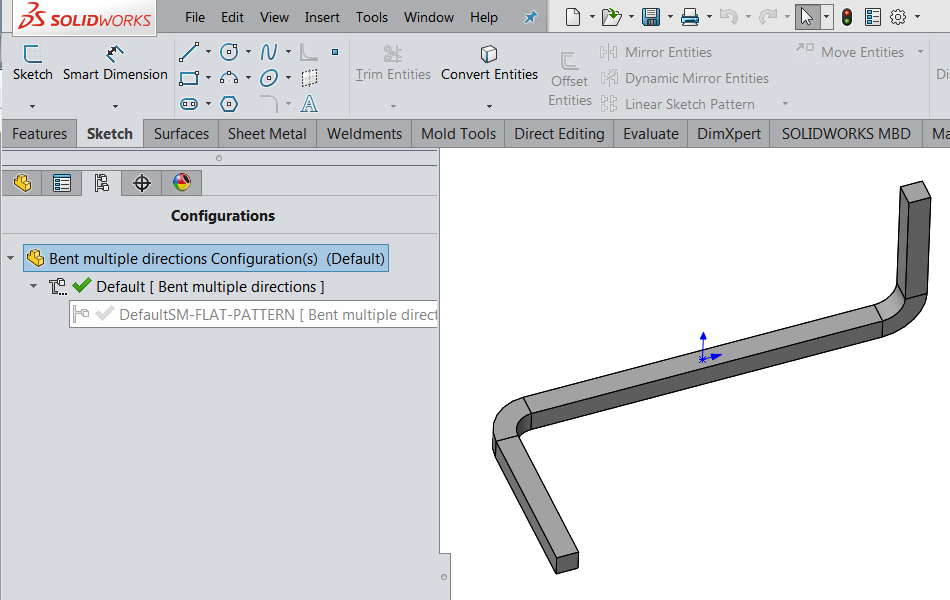

Convert to an open sketch either inner or outer arc and rest of them to construction. For more solidworks tips and tricks please visit the solid. However when i go to convert sheet metal i have no luck. The convert to sheet metal command lets you specify the thickness bends and rips necessary to convert a solid part to a sheet metal part.

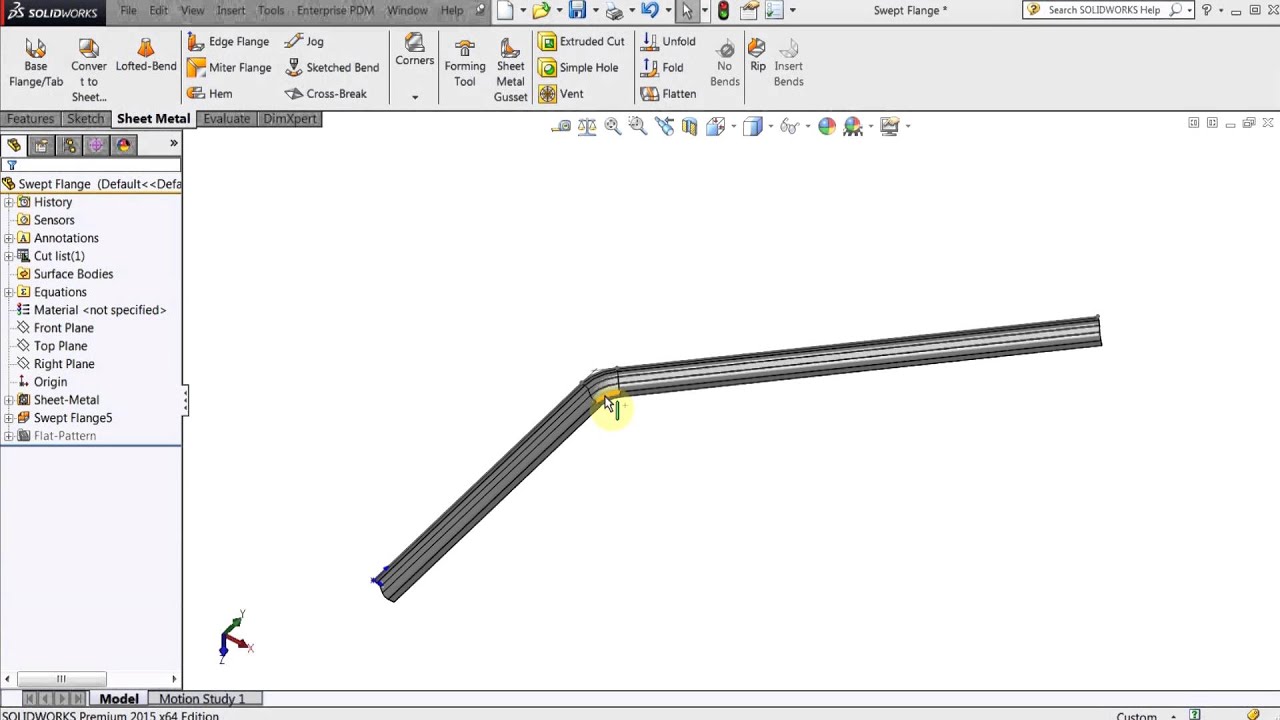

If you don t have the sheet metal tab open right click in the area where the 1 arrow points then click sheet metal. I m doing insert sheet metal convert to sheet metal. In the swept flange feature select flatten along path and add correct thickness. Click convert to sheet metal sheet metal toolbar or insert sheet metal convert to sheet metal.

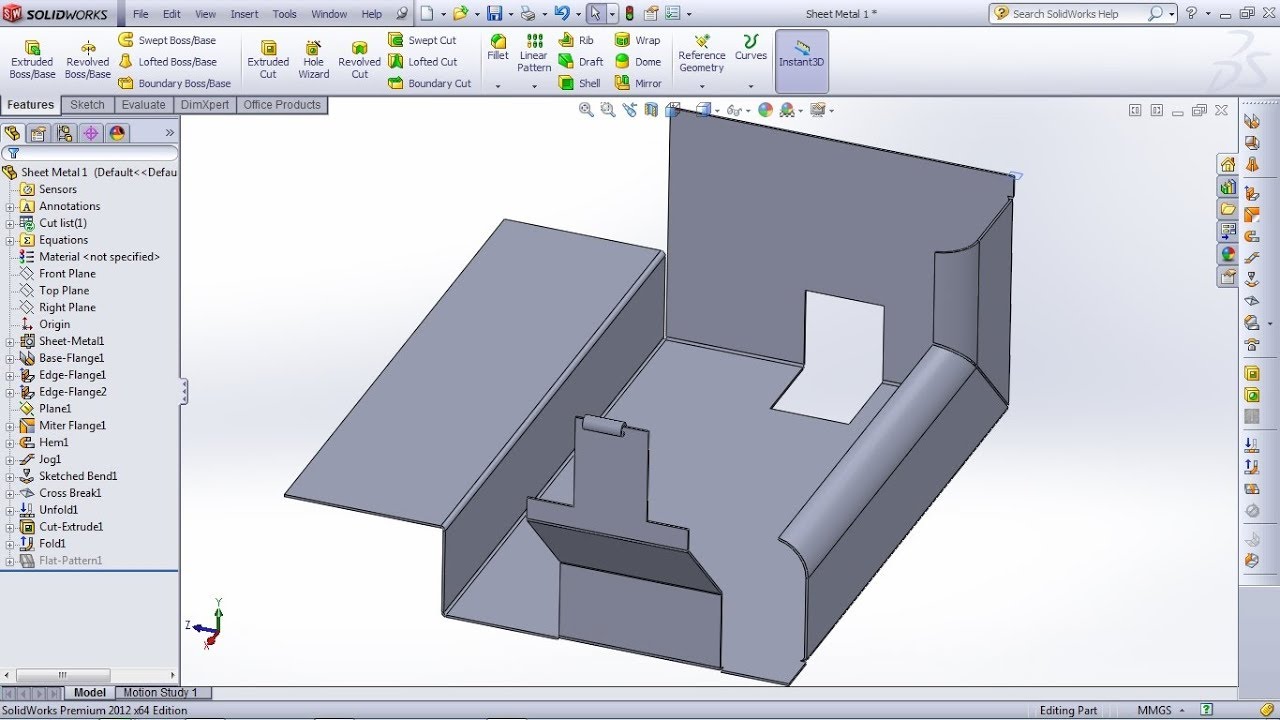

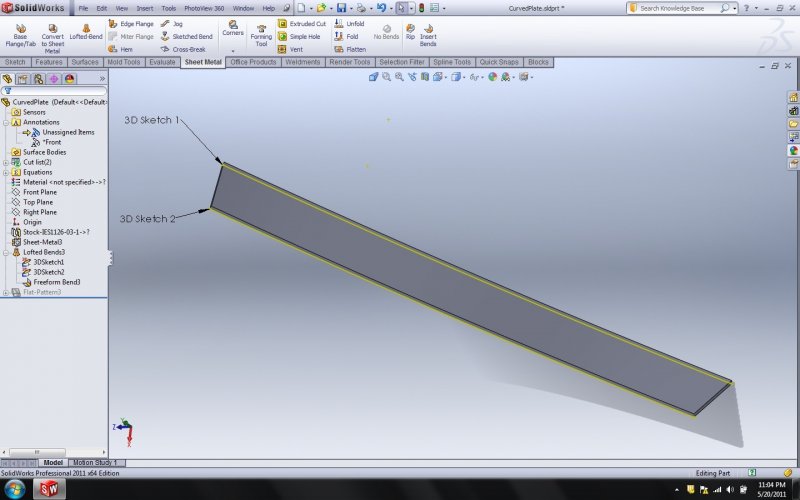

Click convert to sheet metal 3. This video shows the difference between creating a sheet metal part from scratch and converting a solid part to sheet metal. Insert bends is great for an imported model that didn t start out as sheet metal but has a constant thickness. I have recently got into learning surfacing in solidworks 2012 and i have been working on some sheet metal components.

Solidworks convert to sheet metal cylinder. How to create a tapered helical spring using the lofted bend sheet metal tool in solidworks 2011. I then click on the face with the slot and the hole on it as the fixed entity. To convert a solid part to a sheet metal part.

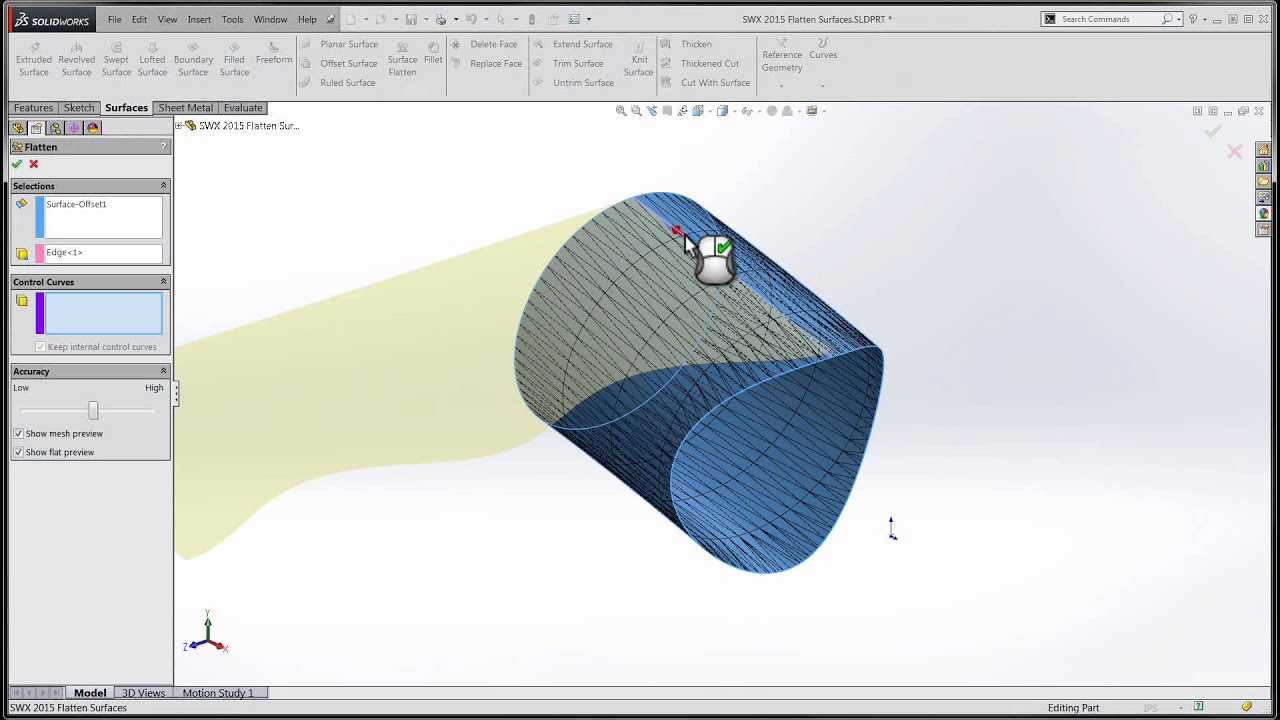

This tutorial shows how to convert cylindrical hollow solid part to sheet metal cylinder. I have been using surfaces with the aim of later converting them to sheet metal. One end of the curve modify to small straight length tangent to the main arc. Bend radii and thicknesses are measured from the model and maintained making this one of the easiest ways to convert any design to a sheet metal part and get a flat pattern even if you don t have any flat faces at all.

The way i have gone about this is simply modeling internal external faces using surfaces.