Crimping Process Sheet Metal

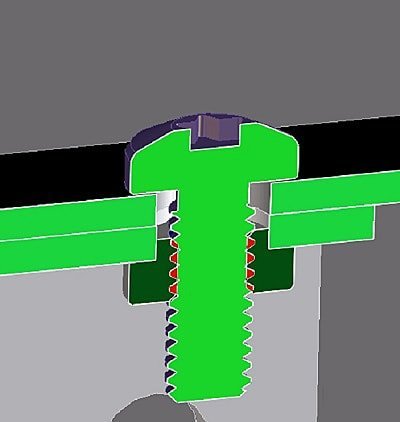

To join two sheets of metal a hole was drilled or punched through and then the solid rivets with a head on one side and a cylindrical shaft were put in most of the time the rivets are fed and placed manually by hand.

Crimping process sheet metal. Crimping is joining two or more pieces of metal or other ductile material by deforming one or both of them to hold the other. Walk the crimper around the pipe circumference in a controlled manner. Metal crimpers crimp fold seam or flatten sheet metal deforming metal to hold itself or become a needed shape for an application. Manufacturers can position wheels for crimp depth down to a thousandth of an inch.

The riveting is carried out in the hole corresponding to the two parts and the rivet gun is used to pull. Sheet metal crimpers are handheld tools that create male crimp bands on various gauges of sheet metal. More product info on the wuko 5000. Crimp tool for 0 14 mm to 10 00 mm insulated and non insulated ferrules f connectors crimped on to coaxial cable.

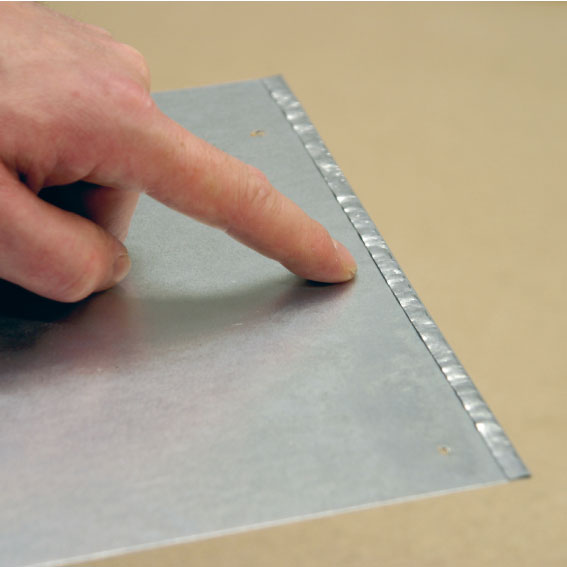

6 types of sheet metal joining techniques folding tab joints. The bend or deformity is called the crimp. Clinching produces a round button type connection between two to four layers of sheet metal. The process can even be used on stainless steel says bruno maczynski engineering manager for tox pressotechnik.

With the pipe or duct seam in closed position start the crimp to one side of the seam by gently tugging on the driver trigger and angling the turbocrimper impact onto the metal edge. Riveting is one of the oldest joining techniques. The telescoping clamp holds the crimper securely to your drill. Proper crimp depth is an important variable in determining the success or failure of the weaving process.

Crimping wheels are placed at an appropriate distance apart to create the crimp depth specified on the job sheet. Last angle the crimper off the metal as the crimper approaches the other side of the seam. The wuko combo bender 5000 is the tool for beading crimping and or offsetting your sheet metal panels. Use on 30 24 ga.

Hand held sheet metal benders for opening seams. The bottom middle cable is missing its crimping collar. Use the power of a drill to crimp the ends of metal duct faster and more evenly than crimping by hand. The two pieces of sheet metal connected to each other by folding or bending tabs in the form of a.