Cutting 125 Aluminum Sheet

Select a fine toothed blade and don t cut aluminum with a wall thickness of more than 1 4 inch 0 64 cm.

Cutting 125 aluminum sheet. Use a wood cutting saw with carbide tipped blades to cut most aluminum. The aluminium cutting system which most modern equipment uses is actually a way of protecting the laser rather than an innovative technique for cutting. Diamond tred aluminum sheet heavy weight model 57575 13 49 13 49. Tired of getting fingers cut on sheet metal while using tin snips.

This system usually takes the form of a back reflection system which can detect if too much laser radiation is being reflected back through the optics. It may damage the machine forever. Set your store to see local availability compare. Lincane aluminum sheet weathered gray model 57565 62 98 62 98.

M d building products 3 ft. If possible choose a saw blade that creates narrow kerfs the notch or slot made by the saw. With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet. The thicker the material and the greater the depth of cut the more important it is to follow these tips.

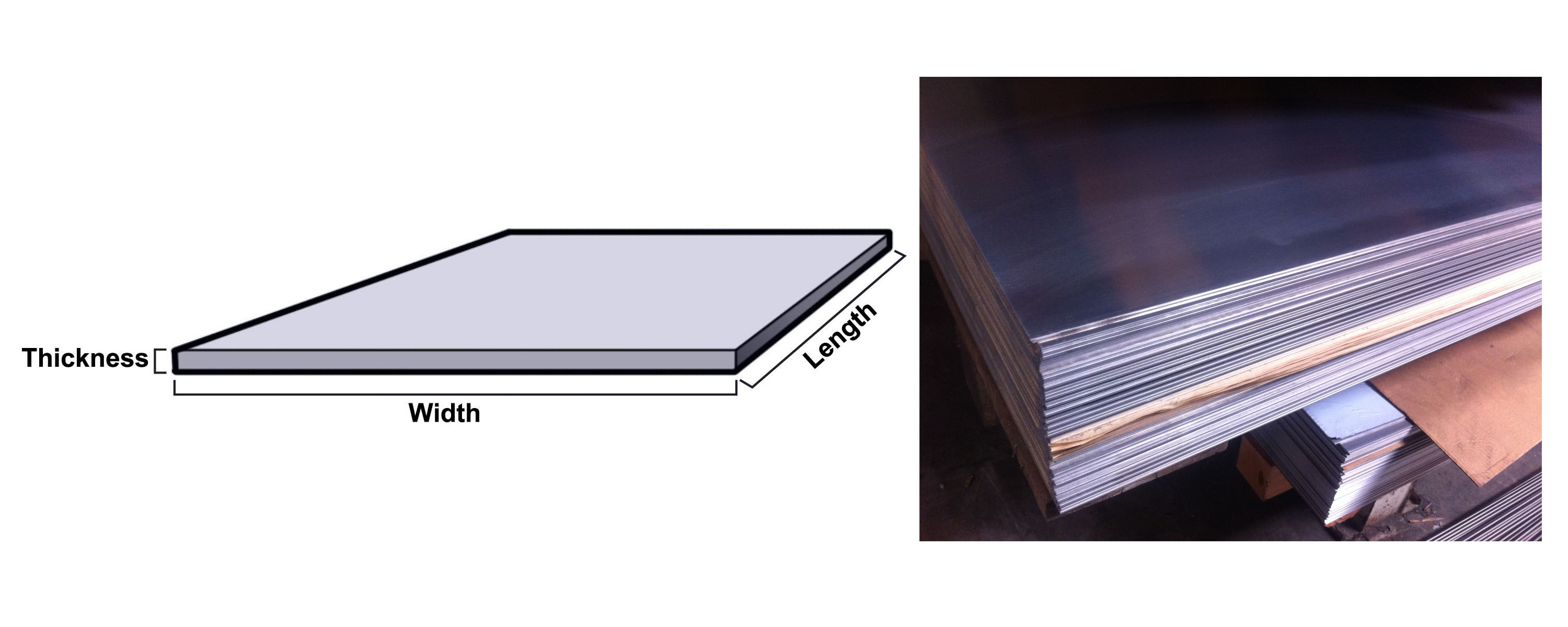

Take into account the high speed machining. Cnc router aluminum sheet work is different than cnc routers cutting aluminum plate. Flip the sheet over and repeat. Avoid dragging the plasma cutter on the surface of the aluminum sheet.

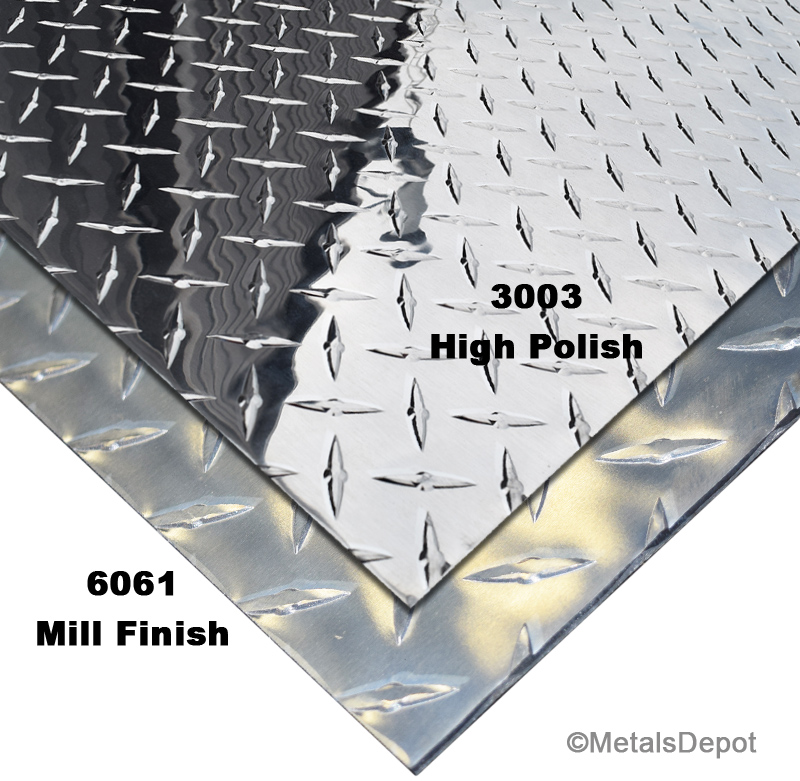

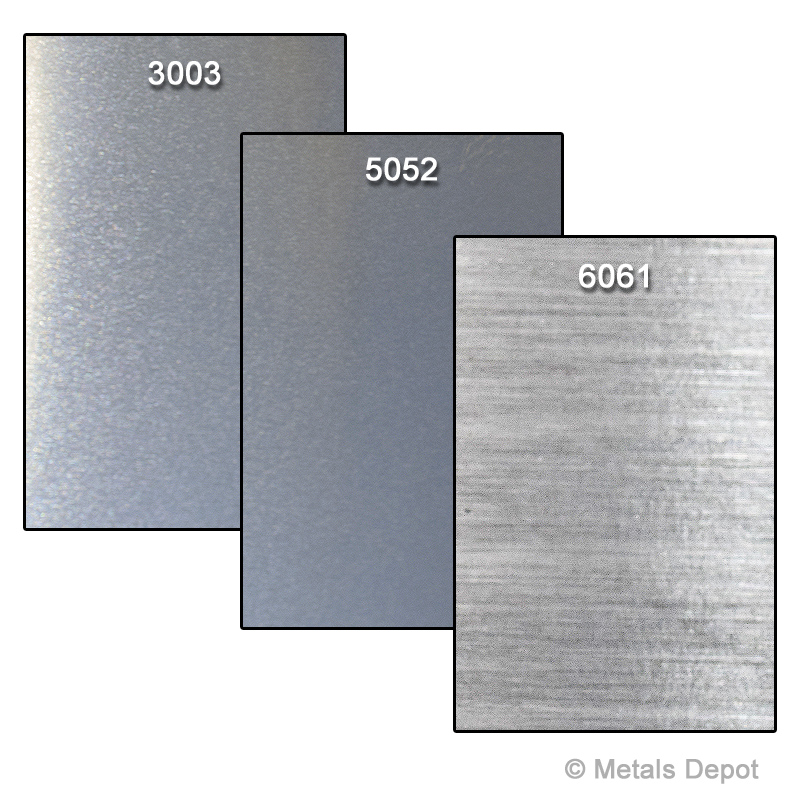

Ryerson offers heat treatable aluminum sheet grades like the popular 6061 aluminum alloy that can be used for commercial applications that require strength corrosion resistance and machinability as well as non heat treatable grades when formability and weldability are priorities. This weakens the aluminium and creates a fracture line. Higher rates of feed 25 inches min 635mm min small depth of cut 0 030 0 75mm max. M d building products 1 ft.

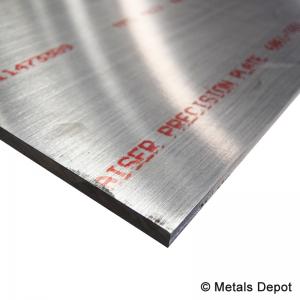

Aluminum sheet metal comes in a variety of thicknesses and weights in many different grades. Check out this video. There s a world of difference for a cnc router cutting thin aluminum sheet vs a cnc router cutting thicker aluminum plate. Place the fracture line over the edge of a table and bend the overhang slightly downwards.