Cutting Quarter Inch Aluminum Sheet

Aluminum also spelled aluminium is one of the most widespread and popular metals on the planet.

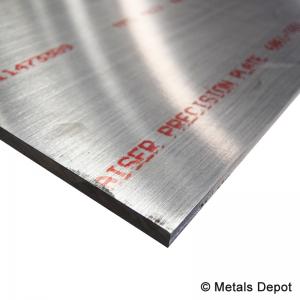

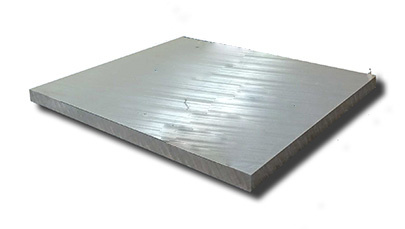

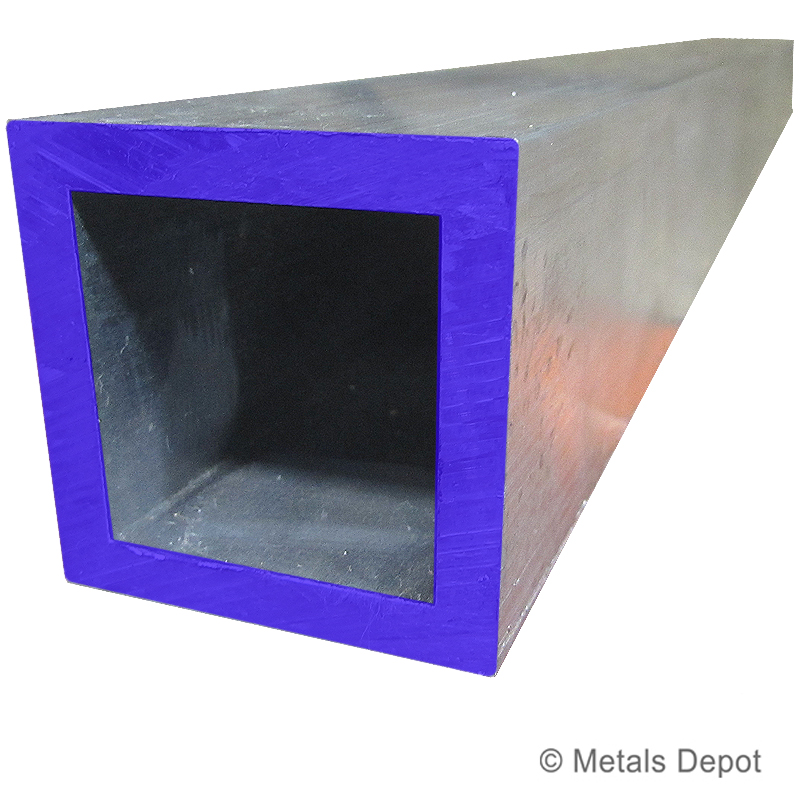

Cutting quarter inch aluminum sheet. 5 pieces 1 4 x 1 aluminum 6061 t6511 solid flat bar 14 long new mill. There s a world of difference for a cnc router cutting thin aluminum sheet vs a cnc router cutting thicker aluminum plate. Afterwards tighten the knob or lever. Get free shipping on qualified aluminum sheet metal or buy online pick up in store today in the hardware department.

I am trying to make some motor mounts so i need to cut a 4 hole and then a wiggly outside edge. Technically anything will eventually get through the plate but this is where you ll see the best performance. 1 4 inch aluminum industrial metal sheets flat stock. Online metals has a variety of shapes and alloys available in full sizes and custom cut lengths.

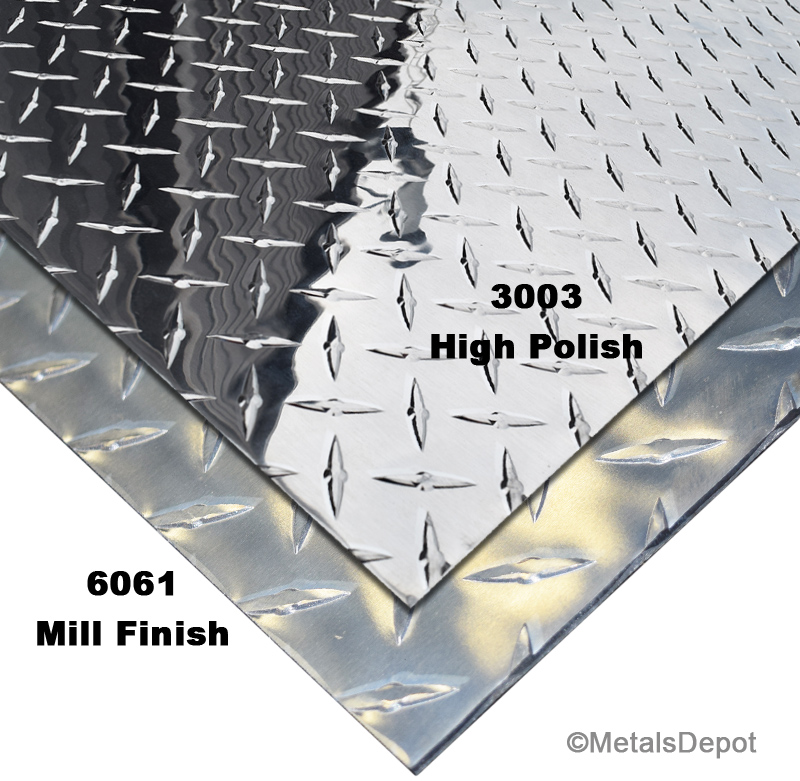

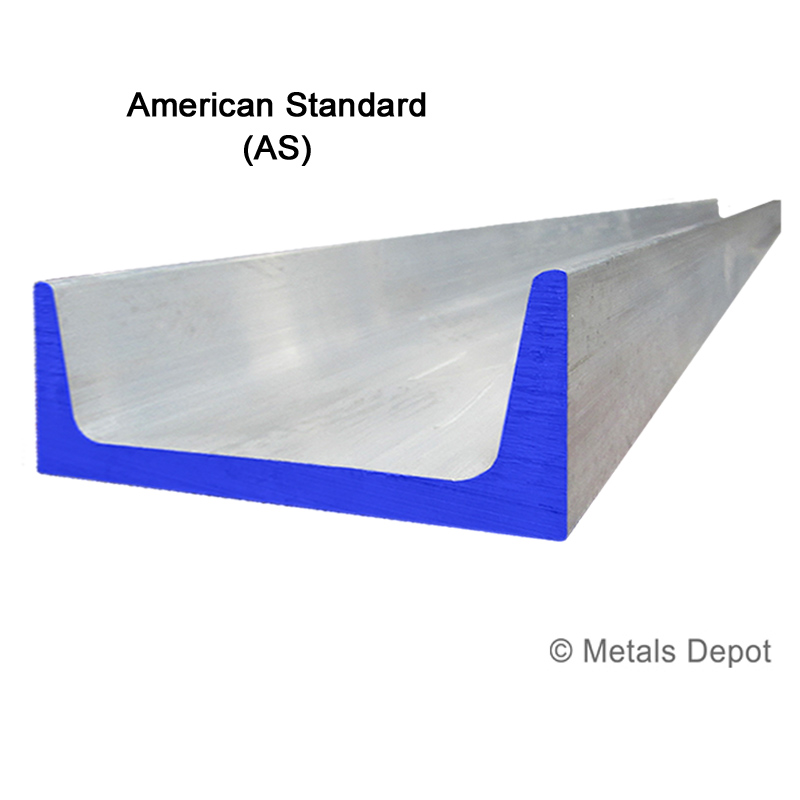

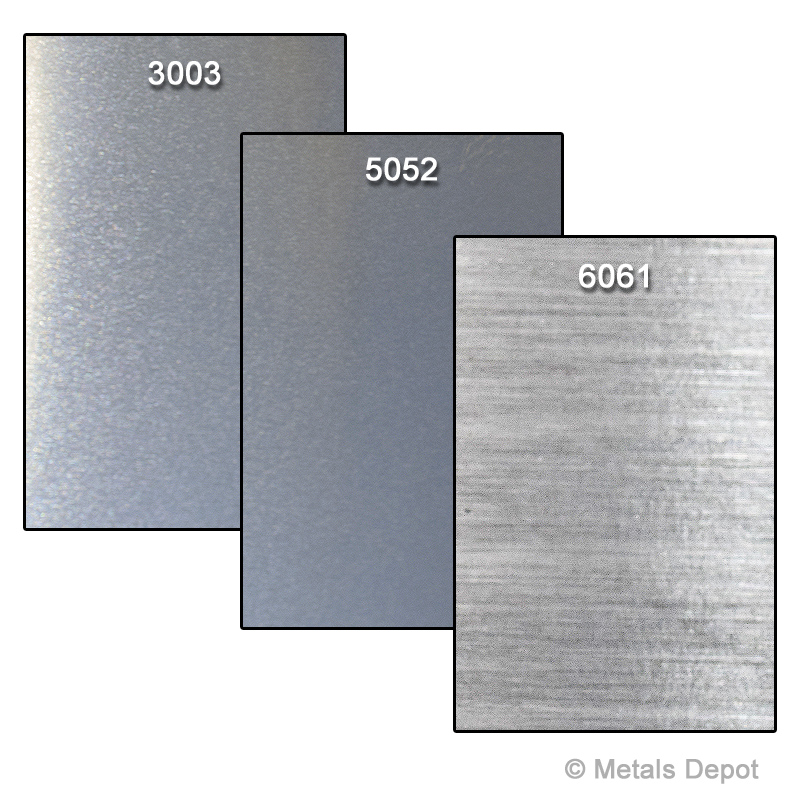

Ryerson offers heat treatable aluminum sheet grades like the popular 6061 aluminum alloy that can be used for commercial applications that require strength corrosion resistance and machinability as well as non heat treatable grades when formability and weldability are priorities. Cnc router aluminum sheet work is different than cnc routers cutting aluminum plate. Clamp or hold a straightedge or square along the cutting marks and score a line with the tip of a sharp utility knife blade. Square up the fabric 2.

Adjust the blade depth so the blade extends 1 4 inch 0 64 cm at most. Cut the fabric in strips as wide as the desired width of the quarter square triangle plus 1 1 4 for seam allowances. 1 4 x 6 aluminum 6061 t6511 flat bar 12 long plate cut new mill stock 25 x6 15 69. I am having trouble cutting 1 4 aluminum plate.

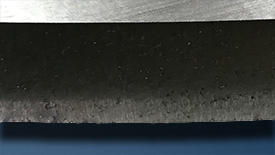

I thought i could just use a jigsaw with a fine tooth blade. Retract the blade guard and hold it beside your aluminum piece. While it s easy to find how you choose where to buy aluminum is important. The ideal tpi for cutting thick aluminum plate is 10 14.

Showing slide current slide of total slides shop by sheet flat stock length. Then bend the sheet back and forth a few times to snap it. Loosen the depth adjustment knob or lever and rotate the base of the saw until the blade is 0 25 inches 0 64 cm below the metal at most. Hello this may sound like a stupid problem question.

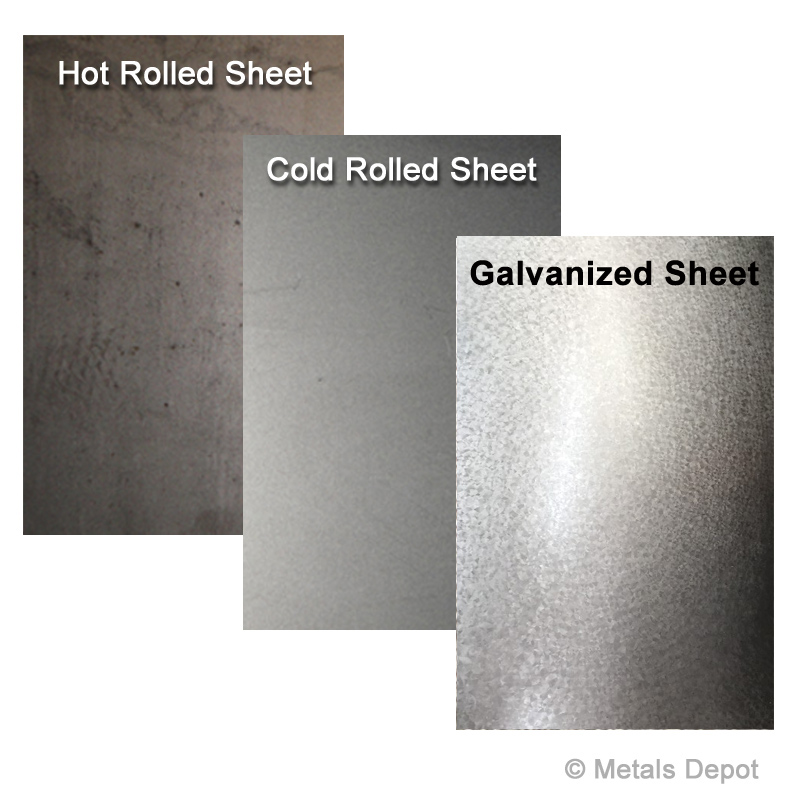

The blade tends to turn into a noodle and binds up. Shop by sheet flat stock length. Aluminum sheet metal comes in a variety of thicknesses and weights in many different grades. If the tooth pitch is too fine there s a high risk that the aluminum chips with clog the blade.

And you can use the same technique anytime you need a straight cut on aluminum or other light gauge sheet metal even steel.