Defects In Sheet Metal Products

The internal structural defects are.

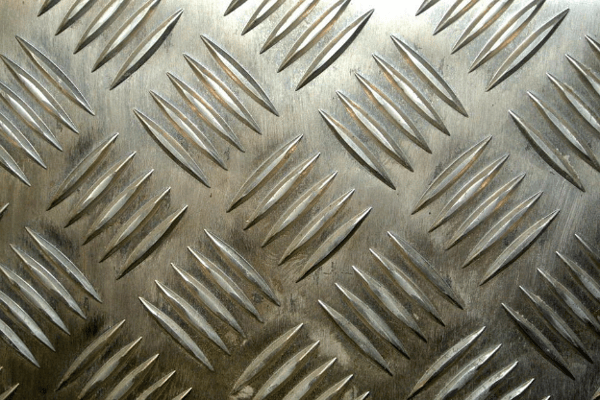

Defects in sheet metal products. Fig 1 these defects are described below. Defects in the final product of mechanically worked metal may have originated from any one or a combination of the following the ingot used for mw may contain defects pores microcracks or inclusions which may remain as such or get aggravated during working operation. Another common defect in sheet metal rolling involves the splitting of a workpiece. The weight doesn t change.

The reason behind it is that welding positions are misaligned. P capital metal industries operates a sheet metal factory. The main reasons for the cracking are over stretching or stress concentration. Internal structural rolling defects.

This can cause an uneven roll with various amounts of pressure throughout the piece. It produces a large selection of unfinished sheet metal products including aluminum carbon steel stainless steel and galvanized metals. There are four main metallurgical processes for the manufacture of finished steel products where the steel products can pick up defects. The defects picked up during these processes are i casting defects ii rolling defects iii forging defects and iv welding defects.

Fracture during forming will take place at the weakest or thinnest point in the part being formed. Surface defects are provided from impurities and inclusion in the material surface roll marks dirt rust and other cause related to prior treatment and working of metal. There are two reasons behind this defect. During the rolling process a piece of metal will experience a different amount of reduction in certain areas of the piece.

Dynamic defects can be corrected by controlling process variables forming forces forming speeds and friction forces and incoming sheet coil properties. Excessive thinning thickening of the sheet during forming wrinkles splits and springback are the three most common defects encountered during sheet metal stamping. Zipper cracks in center of strip. Finishing services such as cutting bending forming and polishing are available p.

One is the improper handling another one is the elasticity of sheet metal forming materials. The occurrence of defects in sheet metal forming and their prevention is a complex subject. It isn t practical to handle this when it s flat so it is coiled as it s produced. This is most likely to be where the sheet has been bent under tension round an angle as extra thinning will occur there.

This means the length of your sheet metal can be over a mile long. Rolling defects wavy edges.