Defects In Sheet Metal Stamping Process

Surface defects such as cracks and necking.

Defects in sheet metal stamping process. The sheet metal forming parts will collide with the surrounding objects in the process of raw material inventory manufacturing. Identifying and resolving the most common defects in sheet metal forming solving common defects in sheet metal forming. Wrinkles splits and springback are the three most common defects. 6 common defects in sheet metal forming.

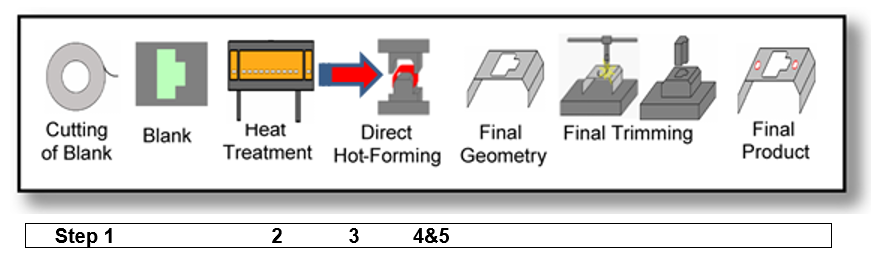

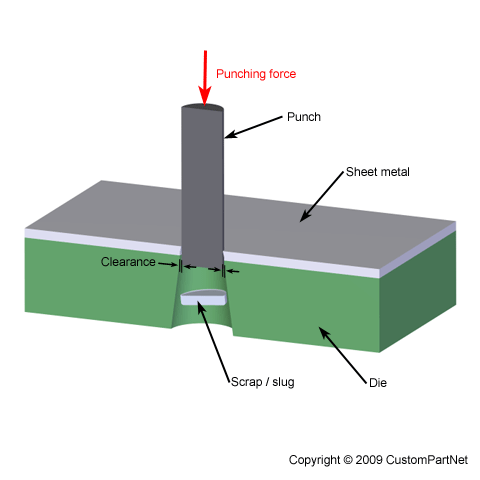

Digital products metal stamping parts defects in forming. Generally if experiencing wrinkles during production this could mean the wrong process was chosen. Defects introduced into 3 52. Surface defects is an important issue in sheet metal stamping as the stamping process affects surface appearance and thus influences surface quality.

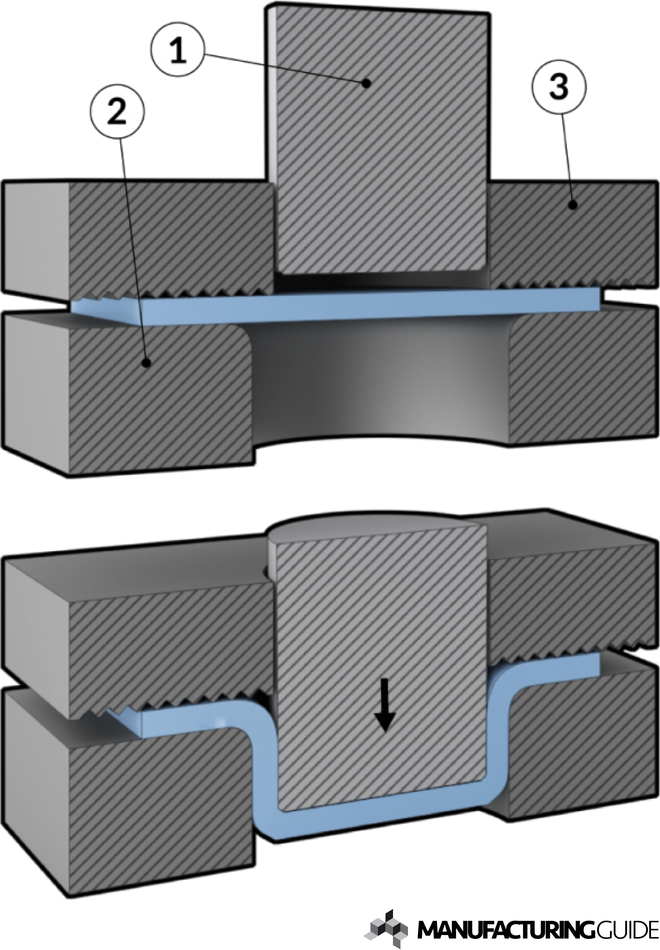

Another common defect in sheet metal rolling involves the splitting of a workpiece. These quality defects can be classified further as static or dynamic. Also known as forming simulation the technology is a specific application of non linear finite element analysis. See figure 1.

How to prevent them. The surface unevenness is mainly caused by the unqualified stamping die. Sheet metal forming simulation is a technology that calculates the process of sheet metal stamping predicting common defects such as splits wrinkles springback and material thinning. This can cause an uneven roll with various amounts of pressure throughout the piece.

Quality custom metal stampings ranging from 003 to 12. Form defects such as fall in wrinkling and marking lines. A great amount of time is therefore spent during the product development process on the optimization of surface defects particularly surface lows during tryout. Metals during fabrication and service.

Static defects such as surface imprints are not process related but instead are caused by contaminated die or tool faces. High surface finish defects at an automotive stamping plant.