Density Of Plain Aluminium Sheet

Plus metals offers a wide range of aluminium sheets to its clients.

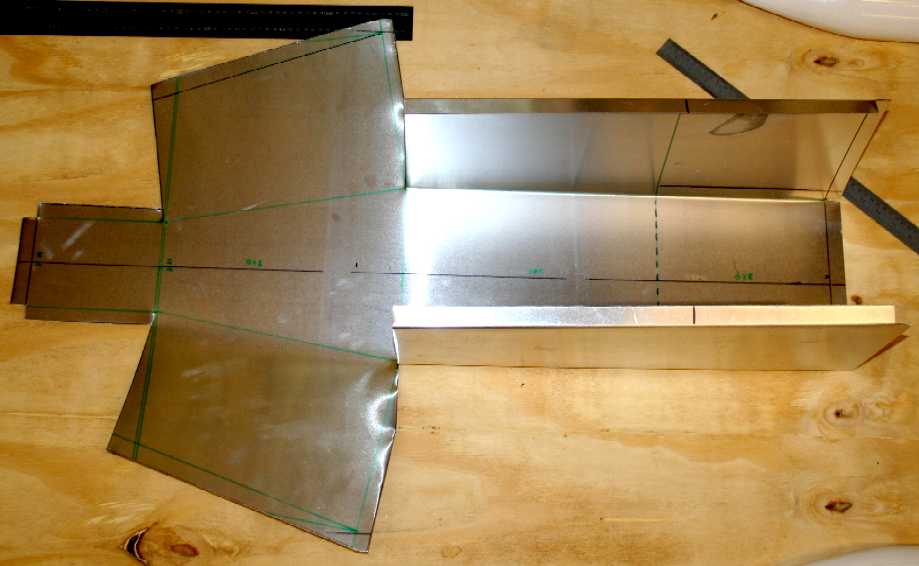

Density of plain aluminium sheet. Aluminium sheet weight chart. Sheet metal gauge size chart gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet. As can be seen from the chart the density of individual alloys can vary from 2 63 to 2 85 g cm3 0 095 to 0 103 lbs in3 or 7 7. S i i when it is not possible to test the base metal before galvanizing the base metal may be tested after stripping offthe zinc coating.

Density table of metals and alloys. Steel aluminium and stainless steel are the most used construction materials. It is also important to know the weight for machining metal sheets no matter the material. The equivalent thicknesses differ for each gauge size standard which were developed based on the weight of the sheet for a given material.

Hope it is of help to you. Weight calculator for sheet metal. The table below lists out the density values of common metals and alloys including iron carbon steel steel wire alloy steel bearing steel stainless steel copper brass bronze aluminum magnesium nickel zinc lead etc. 5 1 2 forcorrugated sheets the maximum phosphorus content maybe0 09 percent.

A zr ti limit of 0 25 percent maximum may be used with this alloy designation for extruded and forged products only but only when the supplier or producer and the purchaser have mutually so agreed. Below is the density table of various sheet metal materials. Aluminium alloy 1050 is a popular grade of aluminium for general sheet metal work where moderate strength is required. A precise weight calculation is extremely important for big metal constructions in the the transport sector and for lifting facilities.

Nonferrous metal close analogs. Gauge and weight chart for sheet steel galvanized steel stainless steel aluminum and strip tubing sponsored links wire gauge is a measure for the size of a wire either in diameter or in cross sectional area. 1050 is known for its excellent corrosion resistance high ductility and highly reflective finish. Therefore in calculating the weight of a component it is important to use the density of the alloy concerned.

.jpg)

.jpg)