Clear Acrylic Sheets Thermoforming

Javascript is disabled on your browser.

Clear acrylic sheets thermoforming. Accepts paint see more product details. Resists stress cracks and chipping forming temperature. Contact us locations about us track shipment register log in cart the leader in plastic sheets rods tubing profiles components 1 888 995 7767. 3 x research source.

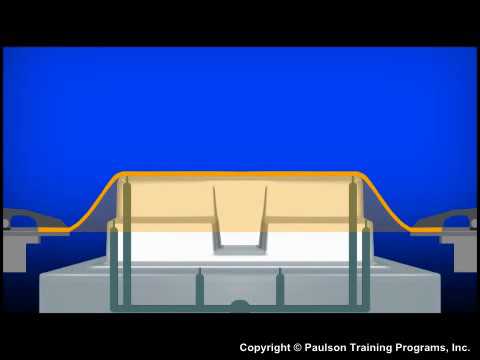

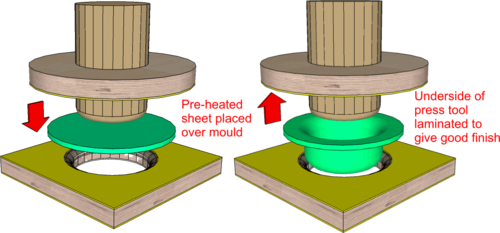

Thermoforming acrylic and pvc sheet in eplastics large oven. Amorphous plastics like abs and polycarbonate generally have wide processing windows and good melt strength making them easy to thermoform. Some plastics like hdpe and pp have narrower processing windows and lower melt strength which make them more difficult but not impossible to thermoform. Place the plastic sheet on a cookie sheet and place in an oven set to 250 f.

0 020 thick petg 12 x 12 thermoform plastic sheets 12 piece bundle clear petg is smooth on both sides high impact strength. Thermoform plastic sheets for vacuum forming. 4x8 4x10 4x12 6x10 8x10 in clear. We stock a complete selection of clear uv resistant plexiglas clear and colored plexiglass infra red transmitting uv filtering uv transmitting and plastic plexiglass mirror acrylic plastic sheets featuring plexiglas brand clear acrylic sheets.

Multiple sheet sizes are available from stock. Thermoforming plastic sheets are available from professional plastics usa singapore taiwan. Petg is also fda food safe and is commonly used to make molds and other kitchen products. Wait about 10 minutes for it to warm fully.

Thermoforming acrylic sheet shop cleanliness is an important factor determining the quality of the parts obtained. It is used for vacuum forming all kinds of clear plastic parts especially blister and clamshell packaging and point of purchase retail displays. Superior graphic supplies petg clear plastic sheets 8 5 inches x 11 inches 020 mil clear 10 sheets thermoforming uv protection 4 4 out of 5 stars 11 18 00 18. When it s ready you ll find it flexible when you try to pick it up.

250 320 degrees fahrenheit cut drill and sand with woodworking tools. It is vital that the thermoforming area is kept clean at all times.

.jpg)