Cold Forming Acrylic Sheet

Cold forming plexiglas sheet can be cold formed bent at room temperature in a smooth arc and held to a radius by forcing the material into a curved channel support.

Cold forming acrylic sheet. It can also shorten the time required to transport the heated sheet from the oven to the forming equipment thus minimizing the possibility of cold forming. This device can reduce appreciably the labor required for clamping and unclamping sheets preparatory to forming. To calculate the minimum bend radius of curvature multiply the thickness of the sheet to be used by 330. To reduce the length of the forming cycle pre dry the sheet in a spare oven and transfer it directly into the forming oven at 176 f 80 c after the drying period.

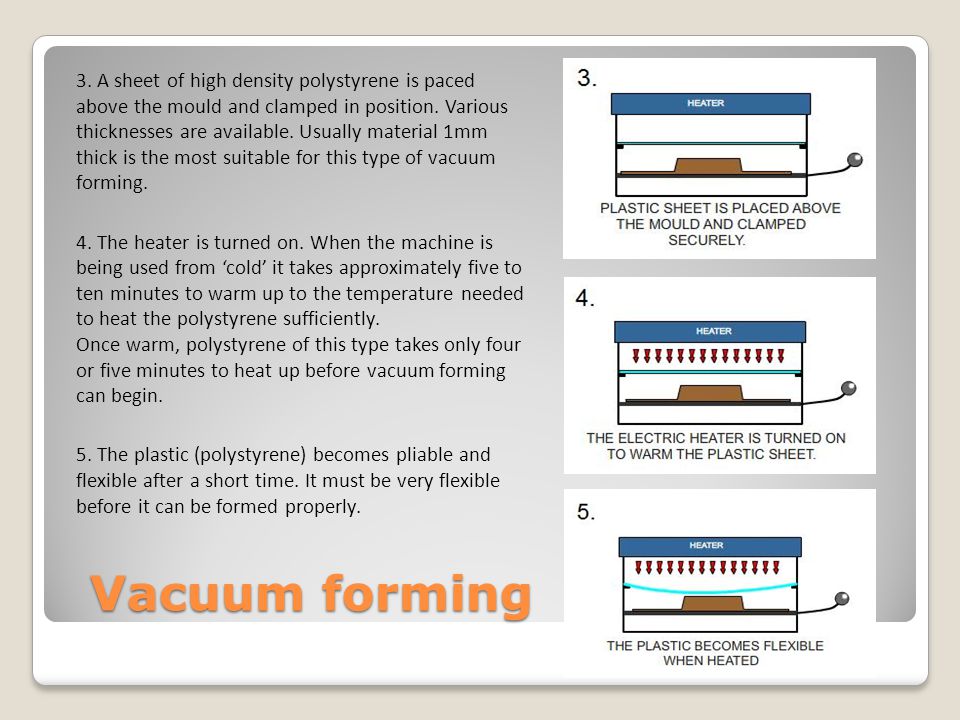

Release mechanism for hanging plexiglas acrylic sheets in heating ovens. Uk educational supply center centre mindsets online sells variously sized 3mm thick sample sheets of eastman s spectar copolyester at not completely outlandish prices. The forming range for acrylic sheet is 290 320ºf 142 160ºc. Extruded sheet should be heated to between 290 and 320 f 145 and 160 c.

Before forming the sheet s temperature must be higher than the desired temperature to allow for cooling that will occur prior to the start of forming. Cold forming is possible. Line bending or thermoforming a brasion resistant acrylic sheet is not recommended. Even temperature distribution throughout the sheet s thickness is recommended.

Acrylite acrylic sheet is offered in several versions. Twenty four hours at 176 f 80 c dries most sheets. Spectar supposedly looks and handles much like acrylic but with the surprising property that it can be cold formed without breaking or whitening and exhibits a memory effect holding a cold bend until reheated.