Conventional Sheet Metalworking Operations

In conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations.

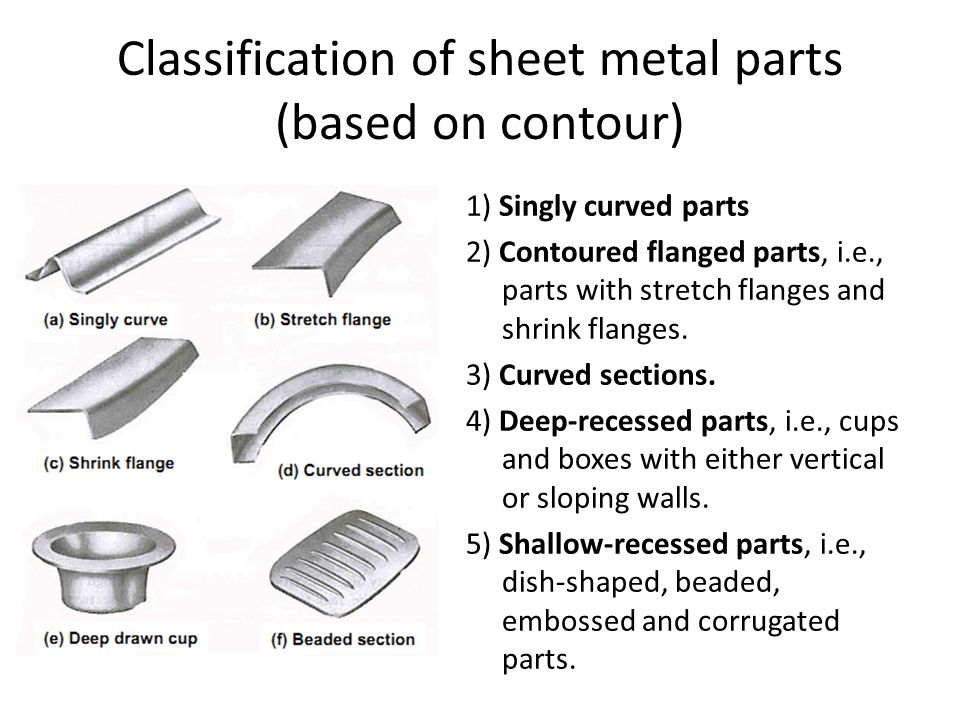

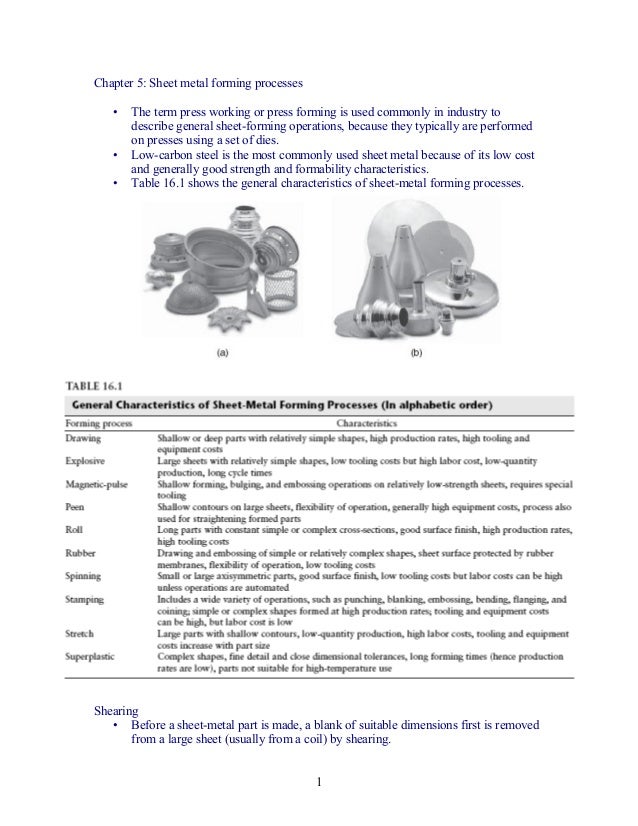

Conventional sheet metalworking operations. Cutting and forming thin sheets of metal usually performed as cold working sheet metal 0 4 1 64 to 6 mm 1 4in thick plate stock 6 mm thick advantage high strength good dimensional accuracy good surface finish economical mass production low cost. A the tooling is called a punch and die. B schematic illustration of one setup for fine blanking. V bending and edge bending.

B the machine tool is called a stamping press. Blanking is an operation of removing a piece of metal from a large sheet by punching with a predefine shaped punch. In edge bending the punch forces a cantilevered sheet metal section over a die edge to. V bending and edge bending.

B examples of various die cutting operations on sheet metal. Module 5 sheet metal operations. Lancing involves slitting the sheet to form a tab. Involves cantilever loading of the sheet metal.

Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity. Describe each of the two types of sheet metal bending operations. Identify the three basic types of sheet metalworking operations. The removed part is called blank and it is the useful part and rest sheet is scrap.

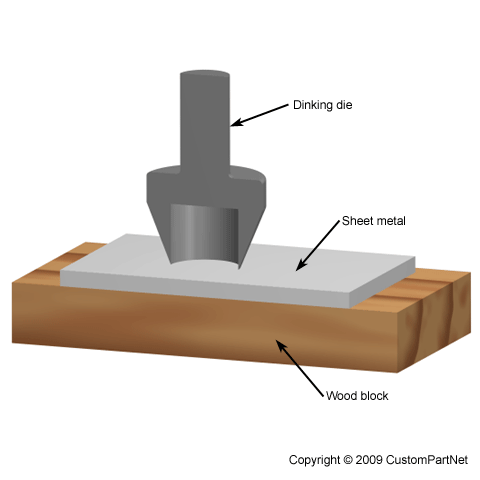

In conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations. Figure 6 slitting with rotary knives. This process is used to cut gears jewelry and complex parts. A punch and die tooling equipment is used in conventional sheet metal working operations.

B stamp presses are the machine tools used in sheet metal working operations to achieve deforming. In v bending a simple punch and die that each have the included angle are used to bend. Figure 5 a comparison of sheared edges produced by conventional left and by fineblanking right techniques. B stamp presses are the machine tools used in sheet metal working operations to achieve deforming.

Obtain the desired bend angle. In conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations. In conventional sheet metalworking operations a what is the name of the tooling and b what is the name of the machine tool used in the operations. The sheet metal is bent between a v shaped punch and die.

Describe each of the two types of sheet metal bending operations.