Cost To Soda Blast Siding

It is ideal for siding applications from new home construction utility buildings planters dog houses and other remodeling or do it yourself projects.

Cost to soda blast siding. It is important to thoroughly remove the residue or you will have adhesion problems with your newly applied finish. Fenders will be an additional cost. The cost to reside a 2 000 square foot home with vinyl is 7 100 on average. Typically to effectively use soda blasting you need to have a blast pot with a specific angle on the.

Fiberglass will be priced 30 over cost of metal cost of zinc is separate and will be an additional 25 cost for each piece over the cost of the blast. You would also have to rent a air compressor that will do 175 185 cfm s in order for the kernel cob blaster to work. Ex hinges brackets each piece is priced separately. Plywood siding features a rough sawn textured face for a beautiful rustic appearance.

We do rent the machine s for 80 00 a day we also sell the grit o cob which is a 40 lb bag and it is 16 00 a bag. We use crushed corn cobs but for siding a medium such as soda will provide a much smoother finished product. House siding costs 4 300 to 15 800 on average or between 3 to 11 per square foot depending on the home s size and materials used. It plywood siding is an all wood exterior grade panel.

Additionally soda blasting is unique because it requires special sandblast pot considerations compared to most abrasive types. The biggest problem with soda blasting wood is neutralizing the soda before you apply a finish. Plywood siding is an all wood exterior grade panel. Any and all pieces that can be removed should be removed from all parts.

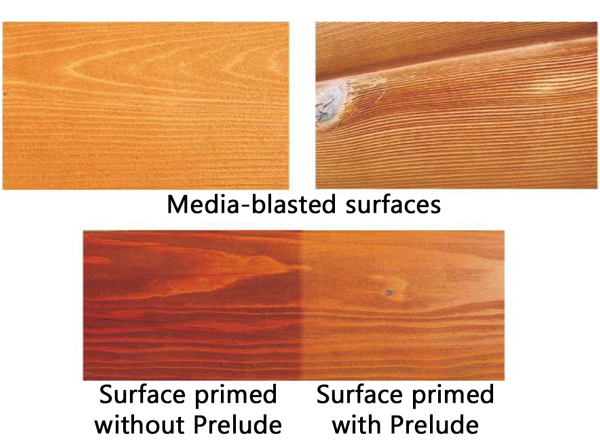

We have estimated that 2 to 3 bags will cover about 100 sq. Media blasting is a high pressure removal process that combines compressed air with a corncob or glass blasting media to produce a very efficient and more importantly a dry log stripping process. Most abrasive blasting cabinets aim to maximize abrasive recycles and minimizing dust collector service and for this reason most sandblasting uses harder abrasives like plastic and glass beads. Soda blasting involves one of the softer abrasive blasting materials rating an average 2 4 on the mohs scale of mineral hardness 1 10.

Soda blasting will not typically remove coating that is strongly adhered to a surface or if it will take a long time. The blasting process removes all of the old stain allows the grain of the log to open and be more receptive to staining.